welding standard

Almost every industry wants to leverage new technologies to produce faster, more cheaply and innovate. In the same way, the manufacturing process follows the same principles. In order to provide high quality at a competitive price, it needs to stay at the cutting edge of technology.

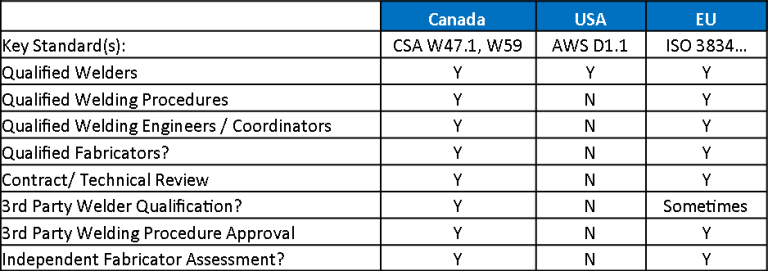

Regardless of where they are located, welders must meet certain criteria. There are no global welding specifications or international standards, even though welding processes and procedures may be very similar. Every country has its own welding standard and codes. Examples of these include Canada, the U.S., and the EU.

This chart outlines the more specific requirements of each standard.

Contact our Customer Service and let us know how we can help to catapult your next project to success.

If you are looking for metal casting services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE or EXPLORE HERE to learn more or .

If you are looking for metal casting services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE to learn more.

Copyright © 2024 Omnidex. All rights reserved.