Permanent Mold Gravity Casting

Permanent Mold Gravity Casting:

A solid choice for high quality casting

Permanent Mold Gravity casting may seem like a straightforward process, but a high level of skill is required to maintain the quality of products. As an experienced Gravity Casting specialist, we follow a series of strict procedures to ensure our products can always meet your expectations.

Meticulous pre-casting preparations

We ensure smooth metal flow and minimal casting defects by pre-heating the casting mold to between 150°C (300°F) and 260°C (500°F). We then apply a ceramic coating to the mold cavities to extend the mold’s working life and make it easier to remove the casting parts.

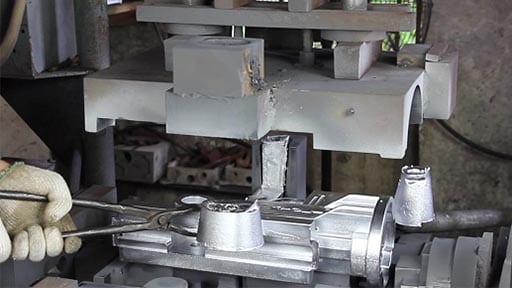

Impeccable craftsmanship

If the pouring process is not done evenly, it may leave visible flow marks on the finished parts. That is why we have our own casting specialists supervising the entire process, ensuring the molten metal is poured into the mold at the right speed. After the casting is done, all sprues and runners are accurately trimmed, then cleaned and painted (if required) by an experienced crew of workers.

Guaranteed quality for our casting processes

Our Gravity Casting process can produce parts ranging from 50 grams to 70 kilograms with good dimensional repeatability and a smooth finish. All material specifications, dimensions and tolerances are closely monitored and maintained by our QC specialists. As with the other casting processes we offer, we guarantee no porosity in our Gravity Casting parts. Learn more about our guarantee here.

Learn more about Permanent Mold Gravity Casting

Permanent Mold Gravity Casting is one of the oldest methods used for casting metals and alloys, dating all the way back to the earliest metal casting activities by mankind. As its name suggests, this process uses “permanent molds” that can be re-used many times, and the pouring process involves only the force of gravity (without the use of pressurized gases, vacuums, or centrifugal force).

The mold for this process is usually made of two halves of iron or steel tooling (male and female halves). Cores made from resin or sand can also be added to make hollow parts. The use of reusable molds makes this process ideal for mass production.

While the production cost can be reduced for repeating production, Permanent Mold Gravity casting is generally more expensive than Sand Casting, but still cheaper than Die Casting.

.

Check out our video on how the process works:

There are also other variations of the process developed to accommodate specific applications. These variations include:

Instead of pouring the molten metal into the mold, it is instead forced into the mold by using low pressure air. This technique ensures the mold remains filled during casting, and helps in reducing shrinkage during the cooling process. It also allows the product to have finer details and thinner cast walls.

Similar to the low pressure technique, this method uses a vacuum to force the material into the mold. It also allows thinner walls, finer details, and better mechanical properties on the product.

In this process, molten metal is poured into the mold and allowed to cool and solidify at the cavity’s surface. When the solidified material reaches the desired thickness, the remaining molten material is poured out of the mold. This technique is commonly used to cast hollow parts without the use of cores.

Pros and cons of Permanent Mold Gravity Casting:

Pros

- Reusable molds

- More precise control over dimensional attributes compare to sand casting

- Can produce more complex shapes and designs compare to sand casting

- Good as-cast surface finish compare to sand casting

- Products have good mechanical properties

- Highly repeatable process, well-suited for high volume production runs

- Can be easily automated

- Low shrinkage and low gas porosity

Cons

- Materials with lower melting temperatures are more suited for this process

- Materials with a high melting point such as cast iron may wear down the mold quickly (the higher the pouring temperature, the shorter the lifespan the mold has)

- Limited part geometry and size

- Higher tooling cost and longer set-up time

- Not a viable option for small-volume production runs

Materials

The best materials for this process are non-ferrous alloys with lower melting points, including aluminium, magnesium, tin, zinc, copper and lead alloys. Materials with a higher melting point are not recommended, as they may wear down the mold more quickly. Common alloys used for this process includes:

| Alloy | Fluidity | Pressure Tightness | Resistance to Hot Cracking | Resistance to Corrosion | Machinability | Elevated Temperature Strength | Anodizing Quality |

| 319 | Very Good | Very Good | Very Good | Good | Good | Good | Fair |

| 333 | Excellent | Very Good | Very Good | Good | Good | Very Good | Fair |

| 354 | Excellent | Excellent | Excellent | Good | Fair | Very Good | Fair |

| 355 | Excellent | Excellent | Excellent | Good | Good | Very Good | Fair |

| 356 | Excellent | Excellent | Excellent | Very Good | Good | Good | Fair |

| A356 | Excellent | Excellent | Excellent | Very Good | Good | Good | Fair |

| 357 | Excellent | Excellent | Excellent | Very Good | Good | Good | Fair |

| A360.0 | Very Good | Excellent | Very Good | Very Good | Good | Very Good | Fair |

| A380.0 | Excellent | Excellent | Excellent | Fair | Good | Very Good | Fair |

- AM100A (10% aluminum, 0.10% manganese)

- AZ81A (7.60% aluminum, 0.70% zinc, 0.13% manganese)

- AZ91C (0.70% zinc, 8.70% aluminium, 0.13% manganese)

- AZ92A (2.00% zinc, 9.00% aluminium, 0.10% manganese)

Due to the temperature and flowability requirements of the process, the use of copper based alloys is limited. These copper alloys can be divided into three groups:

- Yellow Brasses

This group (more specifically C85500, C85800 and B-2) is widely used in the US and Europe for decorative faucets and sanitary fittings. This group is characterized by its conductivity to buffing, polishing and plating. - High Conductivity Coppers

This group of alloys are used for electrical components and are most difficult to cast. They have higher melting points and are susceptible to oxygen pickup. - Engineering Alloys

This group includes silicon brasses, aluminium bronzes and nickel silvers. This group of copper-based alloys are easier to cast using permanent mold processes, with fine finishes, excellent resistance to corrosion and good physical properties. They are widely used to cast cut-out hardware and water pump impellers.

Tolerances

| Nominal dimension (mm) | Linear dimension Tolerances (mm)(ISO8062) | |||

| > | ≤ | CT7 | CT8 | CT9 |

| – | 10 | 0.74 | 1 | 1.5 |

| 10 | 16 | 0.78 | 1.1 | 1.6 |

| 16 | 25 | 0.82 | 1.2 | 1.7 |

| 25 | 40 | 0.9 | 1.3 | 1.8 |

| 40 | 63 | 1 | 1.4 | 2 |

| 63 | 100 | 1.1 | 1.6 | 2.2 |

| 100 | 160 | 1.2 | 1.8 | 2.5 |

| 160 | 250 | 1.4 | 2 | 2.8 |

| 250 | 400 | 1.6 | 2.2 | 3.2 |

| 400 | 630 | 1.8 | 2.6 | 3.6 |

| 630 | 1000 | 2 | 2.8 | 4 |

| 1000 | 1600 | 2.2 | 3.2 | 4.6 |

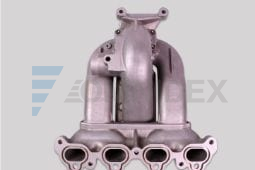

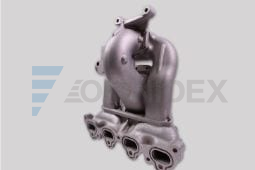

Our Products

Choose the appropriate casting process for your project

Gravity casting can produce parts with excellent mechanical properties and good surface finishes. This process is also known for its good dimensional repeatability and a reduced need for machining. It has many applications in the automotive industry and electrical industry, including engine components, gears, wheels, insulating flanges, brackets, hand levers and valve bodies, just to name a few.

If you need to produce relatively complex parts with finer surface finishes and tighter tolerances, you should probably consider permanent mold casting over conventional sand casting. It is also a good alternative for die casting, offering lower production costs and better ductility in the product.

Are you looking for a metal casting solution for your next project? Omnidex can help you assess your project and offer exceptional solution most-suited for your needs. Don’t forget to check out other casting processes on our website!

Recent Blog Posts

A Brief Overview of Metals Physical Properties

There are many ways to distinguish materials based on their physical properties. Metallurgy studies often look at physical properties as a broader category than mechanical properties. However, not all properties overlap. Using testing methods, physical properties can be distinguished from mechanical properties. In contrast to measuring mechanical properties, measuring physical properties does not require applying force to the material.

Steel is comparatively inexpensive compared to many other metals, which makes it an ideal metal for many projects. Cookware and cutlery, surgical instruments, industrial equipment, and outdoor site furnishings are often made from stainless steel, which has a bright finish and is non-reactive.

The properties and advantages of stainless steel and steel are different, and it is important to understand the differences in aesthetics, properties, and costs before choosing one alloy over the other.

Compare Corrosion Resistance and Cost of Steel and Stainless Steel

Stainless steel and steel are both reliable metals, used in a wide range of applications, from large to tiny components. Which is the better option? Basically, it all depends !

Steel is comparatively inexpensive compared to many other metals, which makes it an ideal metal for many projects. Cookware and cutlery, surgical instruments, industrial equipment, and outdoor site furnishings are often made from stainless steel, which has a bright finish and is non-reactive.

The properties and advantages of stainless steel and steel are different, and it is important to understand the differences in aesthetics, properties, and costs before choosing one alloy over the other.

An Overview of Industrial Valve Types and Applications

A valve is used in almost every situation that involves the flow of liquid or gas. You control the flow of water through your kitchen sink with a valve. A gas stove brings propane gas into its burners through a different valve. Outside the home, industrial valves are designed to withstand high pressures, either from fluids or gases, and to last for years in harsh conditions. Almost every utility, whether water, oil or gas, could not operate without heavy-duty, industrial-strength valves.

Advantages and disadvantages of Water Jet Machining (WJM)

The Water Jet Machining (WJM) process is an advanced, non-conventional machining process wherein a water jet is fired at the workpiece. The jet erodes the material of the workpiece and causes it to become shaped, i.e. jetting is a machining process that utilizes a water jet to remove material from a workpiece…

Iron vs Steel: What are the Differences Between Metal, Iron and Steel

Today, we can’t imagine a world without metal structures, which are used in everything from the car industry to construction. Despite the fact that concepts like iron, steel, and metal are used every day, many still wonder if there is any difference between them. Iron, metal, and steel are all commonly used as synonyms, and this is one of the most common mistakes made every day…

We are always ready to help with your latest project.

Contact our Customer Service and let us know how we can help to catapult your next project to success.

Our Locations

China Office

- 705, Building No.7, Beijiaochang Henglu 1, Guangzhou 510050, P.R. China

- +86 20 8388 7080

- info@omnidexgroup.com

Vietnam

- 3rd Floor, Sumikura Tower, 18H Cong Hoa Street, Ward 4, Tan Binh District, HCMC, Vietnam

- +86 20 8388 7080

- info@omnidexgroup.com

United Kingdom

- Unit 5, Lyneburn Industrial Estate, Dunfermline, Scotland KY11 4JT

- +44 (0) 1383 277077

- laser@omnidexgroup.com

For Other Locations

- Asia Pacific, South America, Africa and rest of the world:

- +86 20 8388 7080

Omnidex Group

The Omnidex Group Brochure

If you are looking for metal casting services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE or EXPLORE HERE to learn more or .

Copyright © 2022 OmnidexCN. All rights reserved.